Truck WeighBridges and Bulk weighing systems

At Truck Weighbridge, we offer a comprehensive range of new and used weighbridges for sale at affordable prices.

Available across Australia all of our reliable products are of a high quality and will function precisely, ensuring your business runs smoothly and efficiently.

We are an Australian owned company and are committed to providing a level of customer service that leaves our customers completely satisfied with the overall experience. Our knowledgeable team are fully trained and qualified to answer any questions and ensure you receive the best trade approved weighbridge for your individual needs.

What Truck WeighBridge Offer

Truck Weighbridge focus on the supply of quality trade approved weighbridges to customers who have the capacity to manage the installation themselves. Customers who self-install their weighbridge typically save thousands of dollars in comparison to those who undertake turn key weighbridge installation projects.

Who do we supply weighbridges to?

The typically customers that Truck Weighbridge assist with the supply of Weighbridges are:

Trade customers including local governments, waste transfer stations and bulk handling facilities – These customers use weighbridges to weigh goods such as farm produce or scrap metal and then use the weight as a means of setting a price to buy or sell the goods.

Agricultural Business and Farms – Our clients in this sector use weighbridges to record weights of produce carted to processing facilities and ensure the that they are meeting their Chain of Responsibility legislative requirements.

Transport operators – Our clients in this sector use weighbridges to meet meeting their Chain of Responsibility legislative requirements and maximise their loads while minimising the risk of large fines due to overloads.

Considerations When Installing a Weighbridge

View our range of trade approvable weighbridges

Truck Weighbridge are fully certified by the National Measurement Institute to supply trade approved Weighbridges.

Truck Weighbridge are fully certified by the National Measurement Institute to supply trade approved Weighbridges.

Our trade approved weighbridges range from 5 meters to 24 meters with capacity from 20,000kg to 80,000kg.

Need Advice? Let our helpful team assist

Request a call back from a team member

What is a truck weighbridge and how does it work?

A truck weighbridge, also known as a truck scale or weigh station, is a large platform that is designed to weigh trucks and other heavy vehicles. It is typically used for commercial purposes, such as determining the weight of goods being transported, verifying compliance with weight regulations, calculating tolls or fees, and optimizing load capacity.

Truck weighbridges work using the principle of static weighing. When a truck drives onto the weighbridge, it rests on a set of load cells or sensors that are strategically placed underneath the platform. These load cells measure the force applied by the weight of the truck, which is then converted into an electrical signal. The electrical signal is transmitted to a weight indicator or terminal, where it is processed and displayed as the weight of the truck.

Here’s a step-by-step overview of how a truck weighbridge works:

- The truck drives onto the weighbridge platform and comes to a stop.

- The weight of the truck is transferred through the tires to the load cells or sensors underneath the platform.

- The load cells or sensors measure the force applied by the weight of the truck and convert it into an electrical signal.

- The electrical signal is transmitted to a weight indicator or terminal.

- The weight indicator or terminal processes the electrical signal and displays the weight of the truck on a digital display or output it to other systems for further processing.

- The truck driver or operator can then obtain the weight measurement for record-keeping, compliance, or other purposes.

It’s important to note that truck weighbridges need to be properly calibrated and maintained to ensure accurate and reliable weight measurements. Calibration and maintenance requirements may vary depending on the type and model of the weighbridge.

What are the different types of truck weighbridges?

There are several different types of truck weighbridges available, which can vary in their design, installation method, and functionality. Some common types of truck weighbridges include:

- Pit-mounted weighbridge: This type of weighbridge is installed in a pit or depression in the ground, with the weighing platform flush with the ground surface. Pit-mounted weighbridges typically require more installation effort and construction work, but they can provide a level surface for vehicles to drive on and off, and they may have better protection against environmental factors such as water and debris.

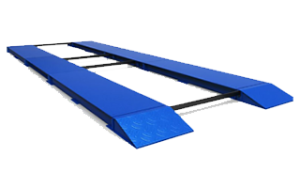

- Surface-mounted weighbridge: This type of weighbridge is installed on the ground surface, without the need for a pit. Surface-mounted weighbridges are relatively easier to install compared to pit-mounted weighbridges, as they do not require extensive excavation or construction work. However, they may require ramps or approaches for vehicles to access the weighing platform, and they may be more exposed to environmental factors.

- Modular weighbridge: This type of weighbridge consists of prefabricated modules that can be assembled on-site to create a complete weighbridge. Modular weighbridges are known for their flexibility and ease of installation, as they can be quickly assembled and disassembled, and they can be easily relocated or expanded. They are particularly useful in temporary or mobile weighing applications.

- Axle weighbridge: This type of weighbridge is designed to measure the weight of individual axles or wheels of a vehicle. Axle weighbridges typically have multiple platforms or sections that are placed under each axle or wheel, and they can provide detailed weight information, such as individual axle weights, total axle weights, and gross vehicle weight (GVW). Axle weighbridges are commonly used for compliance with axle load limits or identifying weight distribution issues.

- Portable weighbridge: This type of weighbridge is designed to be easily transported and set up at different locations. Portable weighbridges are typically lightweight and compact, and they may come with built-in ramps or approaches for vehicles to access the weighing platform. They are useful in situations where a temporary or mobile weighing solution is needed.

- Multi-deck weighbridge: This type of weighbridge consists of multiple levels or decks that allow for simultaneous weighing of multiple vehicles. Multi-deck weighbridges are commonly used in high-volume weighing applications, such as truck terminals or distribution centers, where multiple trucks need to be weighed quickly and efficiently.

How accurate are truck weighbridges in measuring the weight of trucks?

Truck weighbridges are designed to provide accurate weight measurements of trucks and their loads, typically in kilograms (kg), in compliance with Australian regulations. However, the accuracy of a truck weighbridge can be influenced by various factors, such as the quality and calibration of the weighbridge, the condition of the weighing platform, the positioning of the truck on the weighbridge, and the environmental conditions at the time of weighing.

According to Australian regulations, modern truck weighbridges are required to have a legal-for-trade certification, which ensures that they meet specific accuracy requirements. The accuracy requirements for legal-for-trade weighbridges in Australia typically depend on the maximum capacity of the weighbridge. For example, for a weighbridge with a maximum capacity of 60,000 kilograms (60 metric tons), the allowable error is usually limited to ±0.1% of the applied load, or ±60 kilograms, whichever is greater.

It’s important to note that regular calibration, maintenance, and adherence to safety guidelines are essential to ensure accurate and reliable weighing results in compliance with Australian regulations. Calibration involves verifying and adjusting the weighbridge to ensure it is measuring accurately, and legal-for-trade certification may need to be renewed periodically. Maintenance includes keeping the weighing platform clean, level, and free from debris, and inspecting load cells or other weighing components for any signs of damage or wear. Adhering to safety guidelines includes ensuring proper positioning of the truck on the weighbridge, avoiding overloading or uneven loading, and following safety protocols during operation.

What are the legal requirements for truck weighbridges in Australia?

Truck weighbridges in Australia are subject to legal requirements set by the National Measurement Institute (NMI), which is the regulatory body responsible for measurement standards in Australia. The legal requirements for truck weighbridges in Australia include:

- Legal-for-Trade Certification: According to the National Measurement Act 1960 and the National Measurement Regulations 1999, truck weighbridges used for commercial purposes must be certified as legal-for-trade. This certification ensures that the weighbridge meets specific accuracy requirements and is suitable for use in commercial transactions, such as buying or selling goods by weight.

- Maximum Permissible Error (MPE): Truck weighbridges in Australia are required to meet certain accuracy standards, expressed as a Maximum Permissible Error (MPE). The MPE specifies the allowable error in weighing results and is typically based on the maximum capacity of the weighbridge. For example, for a weighbridge with a maximum capacity of 60,000 kilograms (60 metric tons), the allowable error is usually limited to ±0.1% of the applied load or ±60 kilograms, whichever is greater.

- Calibration: Truck weighbridges in Australia must be calibrated regularly to ensure accurate weighing results. Calibration involves verifying and adjusting the weighbridge to meet the specified accuracy requirements. Legal-for-trade certified weighbridges must undergo initial calibration and periodic re-calibration by a qualified technician or metrologist.

- Maintenance: Truck weighbridges must be properly maintained to ensure accurate and reliable weighing results. Maintenance includes keeping the weighing platform clean, level, and free from debris, inspecting load cells or other weighing components for any signs of damage or wear, and repairing or replacing any faulty or damaged components as needed.

- Safety: Truck weighbridges must be operated in compliance with safety guidelines to ensure the safety of personnel and vehicles. This includes proper positioning of the truck on the weighbridge, avoiding overloading or uneven loading, and following safety protocols during operation.

- Record-keeping: Truck weighbridge operators in Australia are required to maintain records of calibration, maintenance, and weighing results, as per the legal requirements. These records may need to be produced for inspection by NMI or other regulatory authorities upon request.